By: Marco Boer, Vice President, I.T. Strategies

This week, Memjet welcomes Marco Boer to be a guest writer on the Memjet blog.

Marco is the Vice President, I.T. Strategies and recognized as a trusted consultant to the digital printing industry.

The world of commercial print is not an easy one. Declining commercial print output, combined with price increases and supply issues with paper and offset ink have resulted in the continued reduction in the number of commercial print establishments.

And now a new challenge is looming, one that is happening faster than most had anticipated: a lack of qualified labor to run printing plants. With the US economy at full employment, labor is a challenge for most businesses. But it is an even bigger challenge for the printing industry.

According to the Bureau of Labor Statistics, the printing and related support activities industry will have the fourth steepest decline in available labor of any industry, trailing the labor decline in the postal service, publishing, and wired telecommunication.

You can have the most beautiful offset presses with the largest capacities in the world, but if there is no labor, they will sit idle.

Pressure to Automate

The long-term trend towards smaller run lengths has been putting stress upon commercial printers for years. But with fully amortized offset presses, these printer providers have been able to manage by using more labor as their pre-press workload increased with smaller, more frequent runs.

With a strong US economy, the lack of qualified labor is adding unexpected further pressure upon commercial printers to automate and become more efficient.

There are very, very few young people entering the printing business to replace aging and retiring offset operators. Constraints on immigration are further adding to the challenge in what is effectively a manufacturing industry. Consequently, the print industry has no choice but to run printing systems with fewer operators.

This solution is not sustainable. To survive, the printing process needs to become more digital. Unlike offset presses that take multiple operators per press to run, a single operator can operate multiple digital printers.

The Inkjet Evolution

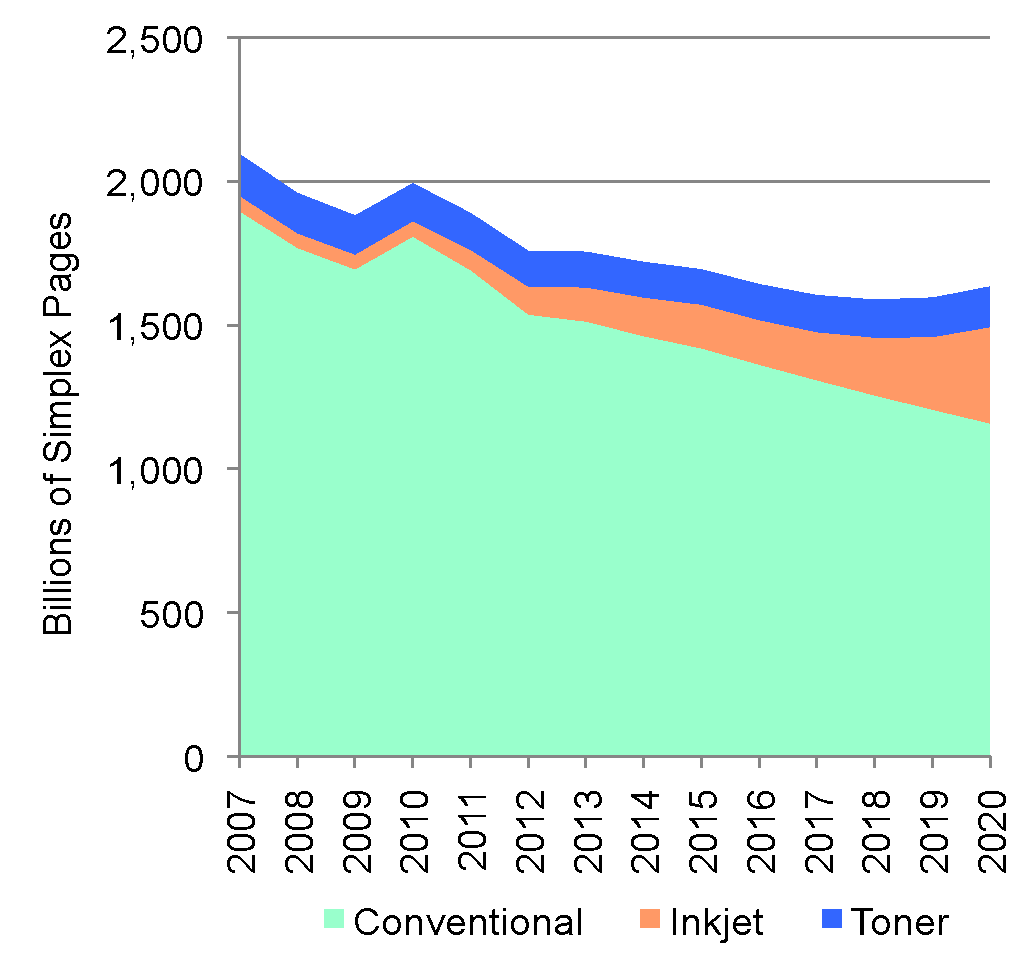

For a while, digital color toner presses have taken up the slack for the high-value, often variable data short-runs. But after 20 years of existence, their limited throughput capabilities and high running costs mean they can only address a little more than 8 percent of all commercial pages printed.

Document Page Volume Trends by Technology, North America

Billions of equivalent simplex pages

Source: NPES Megatrends in Print Study by IT Strategies, 2017

Production inkjet technology, on the other hand, is three to ten times more productive than digital color toner presses. This focus on productivity has enabled inkjet technology to capture over 10 percent of all commercial pages printed in less than 10 years of existence.

Production inkjet printing technology has not yet been able to match the range of substrates on which offset and toner presses can print. So far, this has limited production inkjet mainly to transaction, direct mail, and mostly monochrome book printing applications.

Growing Print by Adding Value

There are, however, two factors that IT Strategies believes will change the acceptance of production inkjet technology for more mainstream document applications like marketing collateral.

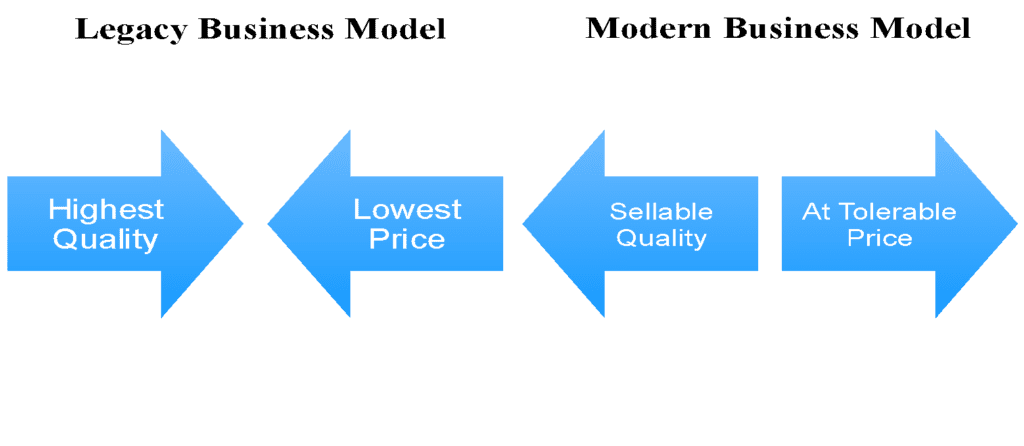

The first change is a realization by commercial printers that no customer is going to pay him more for featuring better print quality or better service than his or her peers. The legacy business model of providing the highest quality at the lowest price is not sustainable; it only results in less revenue and lower margins.

The commercial printers that are making money are doing so by adding value to print through data, analysis, and even variable data printing. By offering their customers insights into how print motivates their customers to respond, they are becoming part of the solution. It changes the print conversation from cost to a conversation about how they can help the customer drive their business.

This transformation is not easy, because it requires deep insight, trust, and investment in resources that have little to do with the actual printing process. It also opens the door to conversations about what print quality is acceptable. Production inkjet may not yet match offset output quality, but it can be quickly established if it is sellable or not sellable. If the value in the output shifts to a conversation about the quality to the value of the content, the commercial printer will have secured his future.

New business models focusing on cost and quality trade-offs

Source: IT Strategies, Inc.

The second factor is improvements in ink technology and pre-coat fluids. The inkjet manufacturers are still in the early phases of trying to find viable solutions – technically and economically – that will allow production inkjet printers to print on standard, low-cost offset stocks. Progress is being made, and the good news is that most of the offerings being introduced are backwards upgradeable for existing inkjet press owners.

IT Strategies expects that the next two years will bring significant breakthroughs in this area, enabling production inkjet printers to capture up to 20 percent of all commercial printed pages.

Regardless of the pace of the breakthroughs, the fundamental overarching problem of a lack of qualified labor is what will drive more commercial printers to inkjet technology. It is going to change commercial printers business models, however uncomfortable that may be. But as Eric Shinseki, US Army General, head of supply management during the Gulf War has succinctly noted: “If you don’t like change, you’re going to hate irrelevance.”

Commercial Print Has Turned the Corner

The good news for the remaining commercial printers is that for those that have the vision and the means, investing in automation will become a little easier in 2018. Changes in the US tax laws allowing full depreciation of capital investments during the year of purchase. IT Strategies expects this to put further pressure – from peers this time – on printers to invest in production inkjet technology.

The commercial print industry has turned the corner: data driven personalization and programmatic marketing campaigns across all print applications are becoming a requirement, not a luxury. Production inkjet is a core part of this requirement, and its growth as a technology is critical to the long-term prosperity of the commercial print industry.