Today, as concerns about the environment grow even more significant, consumers, brands, and businesses are paying increased attention to the impact their choices have on the planet. This demand for more sustainable options has many companies focusing on reducing waste by actively participating in a circular economy. The time is now for the printing industry to embrace this circular economy and improve its impact on a changing marketplace.

What is the Circular Economy?

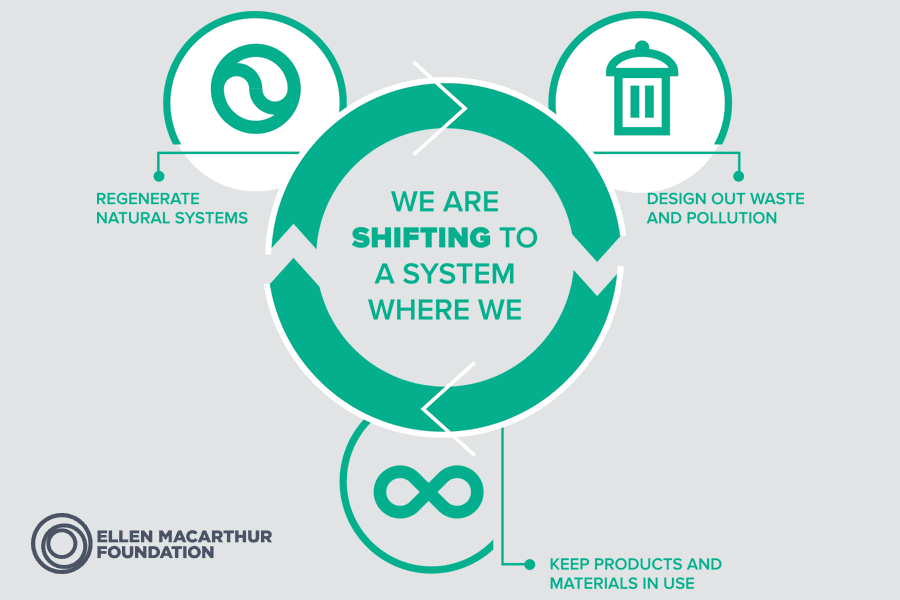

A circular economy requires us to think differently about how we define sustainability. When most people think of sustainability, they think of recycling. While recycling is necessary, in a circular economy, it is the least desirable solution. That’s because recycling relies on materials that are “one-and-done” or single-use. Even when products are described as bio-based materials and biodegradation, it may not be the correct endpoint. After all, landfills are still full of one-time-use products. This kind of indiscriminate waste is terrible for the environment and a company’s bottom line. The principles of a circular economy, on the other hand, provide a new way to think about material use. In this economy, the best way to eliminate waste is to eliminate excess material consumption. In other words, if you don’t want waste, don’t create it in the first place. For a mechanical system, this may include continual maintenance, upgrade, and repair. In a materials sense, this may consist of new ways to reuse or repurpose a resource. A circular economy’s goal is to keep materials in use for extended periods without disrupting the environment.

A Call for Action

Increased attention from Non-Governmental Organizations (NGOs) is forcing governments around the globe to take proactive steps toward a circular economy. Initiatives that include legislative action, penalties, and prevention incentives that address waste creation, including:

- EU Single-Use Plastics Ban — one of the first pieces of legislation to pass in the EU

- EU Circular Economy Framework — legislation targeting ways to increase recycling and reuse throughout a product’s lifecycle while making waste creation more costly

- Quebec bans shrink-sleeves

- NGOs are pushing for Extended Producer Responsibility (EPR) for packaging — this will force paying fees into a scheme to collect plastics packaging

- Maine and Oregon have added legislation to impose recycling fees on manufacturers that include benefits for packaging reduction — a dozen more states are considering this type of legislation.

The Impact of Change

Recent legislative incentives are designed to encourage short-run or on-demand printing to significantly reduce the creation of waste. Such legislation often includes public education efforts in part to encourage consumer participation in accepting new packaging materials or methods. Many forward-thinking companies are already working to move to non-plastic alternatives like paper bottles and Pulpex, which are pulp-based materials. The EU’s single-use plastic ban, and implementation of a plastic recycling “tax” has already started to raise the cost of plastic (especially single-use materials), which will drive supply chains to less wasteful solutions. Packaging that can’t be eliminated or reused must be collected, sorted, and recycled. A responsible design for packaging end-of-life (EOL) is a mono-material design, making recycling more straightforward and effective. Producer take-back programs will be vital in driving high-purity materials streams for reuse.

Digital Printing and the Circular Economy

For brands and print providers who want to actively participate in the circular economy, Memjet technology and inks provide the solution they need. Rather than scrap their existing printing solutions to purchase a separate digital print solution, the modular design of Memjet technology enables customers to upgrade their current, traditional printing techniques with digital printing capabilities. In addition, the use of digital printing allows brands to address the increasing need for smaller manufacturing runs while reducing waste. Packaging printers and converters can reduce inventory and the inevitable scrap of unused packaging that happens today when using traditional analog technology. As a company focused on our environmental impact and that of our customers, Memjet strives to design the safest inks possible without compromising performance – and it starts with water. Memjet’s all-water-based ink portfolio is free from toxic and reactive chemistries, making them safer for the earth and human health than other ink alternatives. Additionally, Memjet’s water-based inks can potentially cut environmental costs (permits and disposal fees) in half. Memjet’s inks intentionally do not contain any of the substances commonly used in other printing ink technologies that are of particular concern to recycling operations, municipalities, state and local regulators. See the White Paper.

Memjet’s printing technology features allow businesses to promptly implement environmental sustainability measures while making the production of their packaging and products more sustainable and cost effective.

Search our partners to find a Powered by Memjet print solution for the market you desire.